2025-07

TapePro++++

Ergonomic, waist-holsterable tape system with magnetic retention and quick indexing.

MAGNETIC RETENTION

To the belt attatchment, your ladder, door frames, or a random piece of metal. Quick indexing that prvides saftey and comfort.

EMBEDDED NEODYMIUM

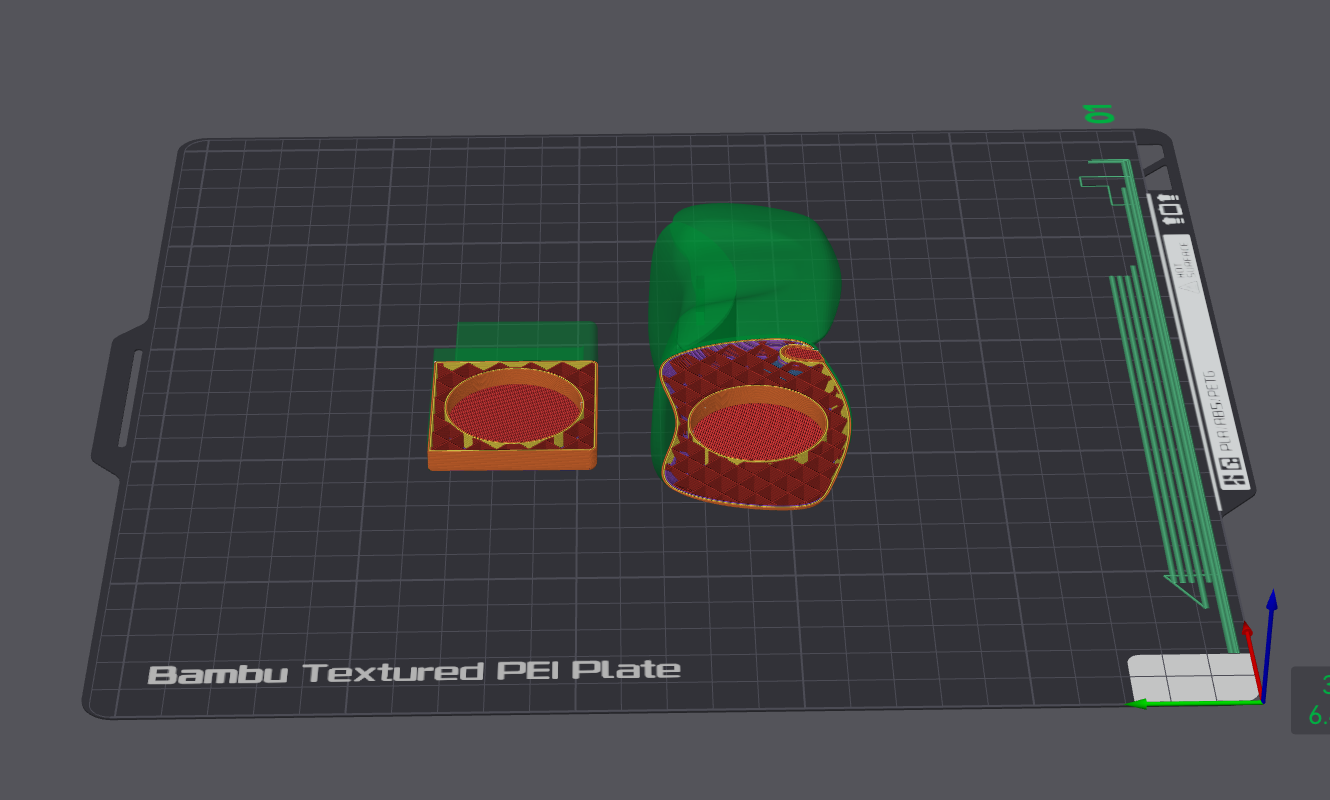

Printed Iterations on X1E Carbon Printers

Business & Market Thinking

Market: pro painters, contractors, DIY. Differentiator: built for tradespeople, not offices. Positioning: “Tape faster. Work safer. Always ready at hand.”

GTM: licensing (Sherwin-Williams / 3M / Stanley), DTC contractor channels, and Amazon Pro Tools.

Outcomes & Learnings

Achieved a functioning prototype with one-handed flow, fast indexing, and safe cutting. Field sessions indicate reduced restart time and less frustration.

The path to DFM is clear: injection molding with a modular blade assembly.

Next Steps

Finalize the cutting mechanism choice, run durability cycles on site, refine holster/magnet hardware, and assemble a licensing package.